Sanding Plate Brake; Working Advice; Sanding Surfaces - Bosch GEX 125 AC - Manuel d'utilisation - Page 9

Table des matières:

- Page 6 – Noise/Vibration Information; Wear hearing protection!; Declaration of Conformity; Assembly; Replacing the Sanding Sheet

- Page 7 – Selecting the Sanding Sheet

- Page 8 – Auxiliary Handle; Operation; Starting Operation; Switching On and Off

- Page 9 – Sanding Plate Brake; Working Advice; Sanding Surfaces

- Page 10 – Maintenance and Service; Maintenance and Cleaning; not; After-sales Service and Customer; Great Britain

- Page 11 – Disposal; Only for EC countries:

English |

21

Bosch Power Tools

1 609 929 N98 | (13.11.08)

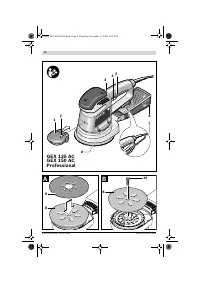

Preselecting the Orbital Stroke Rate

(GEX 125 AC / GEX 150 AC)

With the thumbwheel for preselection of the or-

bital stroke rate

3

, you can preselect the re-

quired orbital stroke rate, even during opera-

tion.

The required stroke rate depends on the materi-

al and the working conditions and can be deter-

mined through practical testing.

The constant electronic control keeps the

stroke rate almost constant under no-load or

load conditions and ensures a uniform working

performance.

After longer periods of working at low stroke

rate, allow the machine to cool down by running

it for approx. 3 minutes at maximum stroke rate

with no load.

Sanding Plate Brake

An integrated sanding plate brake reduces the

stroke rate when running at no-load so that

scoring is prevented when placing the machine

onto the workpiece.

If the no-load stroke rate continuously increases

over the course of time, then the sanding plate

is damaged and must be replaced or the sanding

plate brake is worn. A worn sanding plate brake

must be replaced by an authorised after-sales

service agent for Bosch power tools.

Working Advice

f

Wait until the machine has come to a stand-

still before placing it down.

Sanding Surfaces

Switch the machine on, place it with the com-

plete sanding surface on the surface to be

worked and move the machine with moderate

pressure over the workpiece.

The removal capacity and the sanding pattern

are mainly determined by the selection of the

sanding sheet, the preselected orbital stroke

rate (GEX 125 AC / GEX 150 AC) and the applied

pressure.

Only flawless sanding sheets achieve good

sanding capacity and extend the service life of

the machine.

Pay attention to apply uniform sanding pres-

sure; this increases the working life of the sand-

ing sheets.

Intensifiying the sanding pressure does not lead

to an increase of the sanding capacity, but to in-

creased wear of the machine and the sanding

sheet.

A sanding sheet that has been used for metal

should not be used for other materials.

Use only original Bosch sanding accessories.

Rough Sanding

Attach a sanding sheet with coarse grain.

Apply only light pressure to the machine so that

it runs at a higher stroke rate and high material

removal is achieved.

Fine Sanding

Attach a sanding sheet with fine grain.

By lightly varying the application pressure or

changing the orbital stroke rate (GEX 125 AC /

GEX 150 AC), the sanding plate stroke rate can

be reduced whereby the orbital action is main-

tained.

With moderate pressure, move the machine in a

circular pattern or alternately in lengthwise and

crosswise directions over the workpiece. Do not

tilt the machine to avoid sanding through the

workpiece (e. g. when sanding veneer).

After finishing the working procedure, switch

the power tool off.

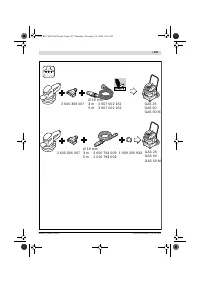

Polishing (GEX 125 AC / GEX 150 AC)

For the polishing of weathered paint or buffing

out scratches (e. g., acrylic glass), the machine

can be equipped with appropriate polishing ac-

cessories such as lamb’s wool bonnet, polishing

felt or sponge (accessories).

Select a low stroke rate (setting 1 – 2) for polish-

ing in order to avoid excessive heating of the

surface.

Apply polishing agent crosswise or in a circular

motion with a polishing sponge and moderate

pressure, and then allow it to dry lightly.

1 – 2

Low stroke rate

3 – 4

Medium stroke rate

5 – 6

High stroke rate

OBJ_BUCH-424-002.book Page 21 Thursday, November 13, 2008 9:49 AM

„Téléchargement du manuel“ signifie que vous devez attendre que le fichier soit complètement chargé avant de pouvoir le lire en ligne. Certains manuels sont très volumineux, et le temps de chargement dépend de la vitesse de votre connexion Internet.

Résumé

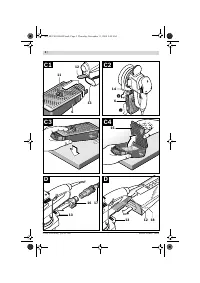

18 | English 1 609 929 N98 | (13.11.08) Bosch Power Tools Noise/Vibration Information Measured values determined according to EN 60745.Typically the A-weighted sound pressure level of the product is 75 dB(A). Uncertainty K = 3 dB.The noise level when working can exceed 80 dB(A). Wear hearing protect...

English | 19 Bosch Power Tools 1 609 929 N98 | (13.11.08) Selecting the Sanding Sheet Depending on the material to be worked and the required rate of material removal, different sanding sheets are available: Selection of the Sanding Plate Depending on the application, the machine can be equipped wit...

20 | English 1 609 929 N98 | (13.11.08) Bosch Power Tools Dust/Chip Extraction f Dusts from materials such as lead-containing coatings, some wood types, minerals and metal can be harmful to one’s health. Touch-ing or breathing-in the dusts can cause aller-gic reactions and/or lead to respiratory inf...